MQ-2 MQ2 Methane Butane Gas Sensor Detection Module

| รหัสสินค้า | SEN-221-02 |

| หมวดหมู่ | เซนเซอร์แก๊ส MQ-2 -> MQ-135 |

| ราคา | 60.00 บาท |

| น้ำหนัก | 10 กรัม |

| สถานะสินค้า | พร้อมส่ง |

| ลงสินค้า | 24 มี.ค. 2559 |

| อัพเดทล่าสุด | 2 ม.ค. 2568 |

| จำนวน | ชิ้น |

รายละเอียดสินค้า

Product Description:

Introduction:

MQ-2 gas sensor sensitive material used in the clean air low conductivity tin oxide (SnO2). When there is the environment in which the combustible gas sensor, conductivity sensor with increasing concentration of combustible gases in air increases. Using a simple circuit to convert the change in conductivity of the gas concentration corresponding to the output signal. MQ-2 gas sensor high on gas, propane, hydrogen sensitivity of detection of natural gas and other flammable vapors are also very good. This sensor can detect a variety of flammable gas, is a low-cost sensors for a variety of applications.

Module Features:

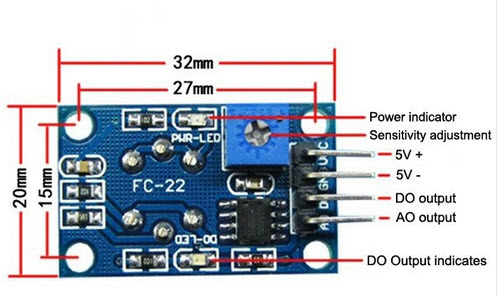

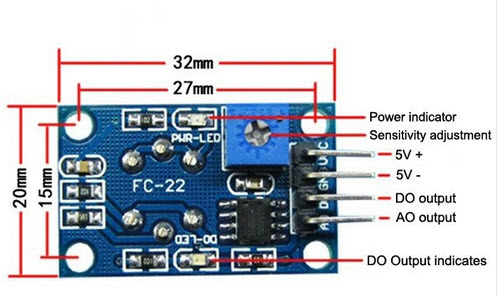

- Using high-quality dual-panel design, with power indicator and TTL signal output instructions ;

- The switching signal having a DO (TTL) output and analog output AO ;

- TTL output valid signal is low . ( Low-level signal when the output light can be directly connected to the microcontroller or relay module )

- Analog output voltage with the higher concentration of higher voltage.

- A gas, natural gas, city gas , smoke better sensitivity.

- There are four screw holes for easy positioning ;

- Product dimensions : 32 (L) * 20 (W) * 15 (H)

- Has a long life and reliable stability

- Rapid response and recovery characteristics

- Chip: LM393, ZYMQ-2 gas sensors

- Working voltage: for DC 5V

- Detection of gas: combustible gases, fumes

- Detectable concentration :300-10000ppm (flammable gas)

Electrical properties:

- Input voltage : DC5V Power consumption ( current ): 150mA

- DO output : TTL digital 0 and 1 ( 0.1 and 5V)

- AO output :0.1-0 .3 V ( relative to pollution ) , the maximum concentration of a voltage of about 4V

- Special note: After the sensor is powered , needs to warm up around 20S, measured data was stable , heat sensor is a normal phenomenon , because the internal heating wire , if hot is not normal .

Pin definition :

1, VCC: positive power supply (5V)

2, GND: power supply is negative

3, DO: TTL switching signal output

4, AO: analog signal output

Applications:

Gas may be used in homes and factories leakage monitoring device suitable for the detection of gas, butane , propane , methane , smoke , etc.

*

*

Theory

The protection resistor (4.7Kohms) and the adjustable (0-50Kohms) are in serial which forms a load resistor RL(4.7-54.7Kohms). The sensor’s resistance RS and RL forms a voltage divider. The output voltage on the signal pin could be read by Arduino or MCU via ADC. Given a value of RL , Power Supply Voltage, and output voltage, RS could be derived. Based on the chart provided in the MQ-2 datasheet, RS in clean air under given temperature and humidity is a constant,which is the “initial” resistance of the sensor named RO. RO of the resistor could be derived from RS. The main job of the calibration is to calculate the RO by sampling and averaging the readings when the module is placed in the clean air. Once the RO is derived, the concentration of target gas could be calculated by using the RS/RO ratio as the input. To achieve more accuracy, a segmented look-up table should be used. However, in the demonstration, a linear formula is used as an approximation to the original curve.

Arduino Sample Code

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

|

/*******************Demo for MQ-2 Gas Sensor Module V1.0*****************************

Support: Tiequan Shao: support[at]sandboxelectronics.com

Lisence: Attribution-NonCommercial-ShareAlike 3.0 Unported (CC BY-NC-SA 3.0)

Note: This piece of source code is supposed to be used as a demostration ONLY. More

sophisticated calibration is required for industrial field application.

Sandbox Electronics 2011-04-25

************************************************************************************/

/************************Hardware Related Macros************************************/

#define MQ_PIN (0) //define which analog input channel you are going to use

#define RL_VALUE (5) //define the load resistance on the board, in kilo ohms

#define RO_CLEAN_AIR_FACTOR (9.83) //RO_CLEAR_AIR_FACTOR=(Sensor resistance in clean air)/RO,

//which is derived from the chart in datasheet

/***********************Software Related Macros************************************/

#define CALIBARAION_SAMPLE_TIMES (50) //define how many samples you are going to take in the calibration phase

#define CALIBRATION_SAMPLE_INTERVAL (500) //define the time interal(in milisecond) between each samples in the

//cablibration phase

#define READ_SAMPLE_INTERVAL (50) //define how many samples you are going to take in normal operation

#define READ_SAMPLE_TIMES (5) //define the time interal(in milisecond) between each samples in

//normal operation

/**********************Application Related Macros**********************************/

#define GAS_LPG (0)

#define GAS_CO (1)

#define GAS_SMOKE (2)

/*****************************Globals***********************************************/

float LPGCurve[3] = {2.3,0.21,-0.47}; //two points are taken from the curve.

//with these two points, a line is formed which is "approximately equivalent"

//to the original curve.

//data format:{ x, y, slope}; point1: (lg200, 0.21), point2: (lg10000, -0.59)

float COCurve[3] = {2.3,0.72,-0.34}; //two points are taken from the curve.

//with these two points, a line is formed which is "approximately equivalent"

//to the original curve.

//data format:{ x, y, slope}; point1: (lg200, 0.72), point2: (lg10000, 0.15)

float SmokeCurve[3] ={2.3,0.53,-0.44}; //two points are taken from the curve.

//with these two points, a line is formed which is "approximately equivalent"

//to the original curve.

//data format:{ x, y, slope}; point1: (lg200, 0.53), point2: (lg10000, -0.22)

float Ro = 10; //Ro is initialized to 10 kilo ohms

void setup()

{

Serial.begin(9600); //UART setup, baudrate = 9600bps

Serial.print("Calibrating...\n");

Ro = MQCalibration(MQ_PIN); //Calibrating the sensor. Please make sure the sensor is in clean air

//when you perform the calibration

Serial.print("Calibration is done...\n");

Serial.print("Ro=");

Serial.print(Ro);

Serial.print("kohm");

Serial.print("\n");

}

void loop()

{

Serial.print("LPG:");

Serial.print(MQGetGasPercentage(MQRead(MQ_PIN)/Ro,GAS_LPG) );

Serial.print( "ppm" );

Serial.print(" ");

Serial.print("CO:");

Serial.print(MQGetGasPercentage(MQRead(MQ_PIN)/Ro,GAS_CO) );

Serial.print( "ppm" );

Serial.print(" ");

Serial.print("SMOKE:");

Serial.print(MQGetGasPercentage(MQRead(MQ_PIN)/Ro,GAS_SMOKE) );

Serial.print( "ppm" );

Serial.print("\n");

delay(200);

}

/****************** MQResistanceCalculation ****************************************

Input: raw_adc - raw value read from adc, which represents the voltage

Output: the calculated sensor resistance

Remarks: The sensor and the load resistor forms a voltage divider. Given the voltage

across the load resistor and its resistance, the resistance of the sensor

could be derived.

************************************************************************************/

float MQResistanceCalculation(int raw_adc)

{

return ( ((float)RL_VALUE*(1023-raw_adc)/raw_adc));

}

/***************************** MQCalibration ****************************************

Input: mq_pin - analog channel

Output: Ro of the sensor

Remarks: This function assumes that the sensor is in clean air. It use

MQResistanceCalculation to calculates the sensor resistance in clean air

and then divides it with RO_CLEAN_AIR_FACTOR. RO_CLEAN_AIR_FACTOR is about

10, which differs slightly between different sensors.

************************************************************************************/

float MQCalibration(int mq_pin)

{

int i;

float val=0;

for (i=0;i<CALIBARAION_SAMPLE_TIMES;i++) { //take multiple samples

val += MQResistanceCalculation(analogRead(mq_pin));

delay(CALIBRATION_SAMPLE_INTERVAL);

}

val = val/CALIBARAION_SAMPLE_TIMES; //calculate the average value

val = val/RO_CLEAN_AIR_FACTOR; //divided by RO_CLEAN_AIR_FACTOR yields the Ro

//according to the chart in the datasheet

return val;

}

/***************************** MQRead *********************************************

Input: mq_pin - analog channel

Output: Rs of the sensor

Remarks: This function use MQResistanceCalculation to caculate the sensor resistenc (Rs).

The Rs changes as the sensor is in the different consentration of the target

gas. The sample times and the time interval between samples could be configured

by changing the definition of the macros.

************************************************************************************/

float MQRead(int mq_pin)

{

int i;

float rs=0;

for (i=0;i<READ_SAMPLE_TIMES;i++) {

rs += MQResistanceCalculation(analogRead(mq_pin));

delay(READ_SAMPLE_INTERVAL);

}

rs = rs/READ_SAMPLE_TIMES;

return rs;

}

/***************************** MQGetGasPercentage **********************************

Input: rs_ro_ratio - Rs divided by Ro

gas_id - target gas type

Output: ppm of the target gas

Remarks: This function passes different curves to the MQGetPercentage function which

calculates the ppm (parts per million) of the target gas.

************************************************************************************/

int MQGetGasPercentage(float rs_ro_ratio, int gas_id)

{

if ( gas_id == GAS_LPG ) {

return MQGetPercentage(rs_ro_ratio,LPGCurve);

} else if ( gas_id == GAS_CO ) {

return MQGetPercentage(rs_ro_ratio,COCurve);

} else if ( gas_id == GAS_SMOKE ) {

return MQGetPercentage(rs_ro_ratio,SmokeCurve);

}

return 0;

}

/***************************** MQGetPercentage **********************************

Input: rs_ro_ratio - Rs divided by Ro

pcurve - pointer to the curve of the target gas

Output: ppm of the target gas

Remarks: By using the slope and a point of the line. The x(logarithmic value of ppm)

of the line could be derived if y(rs_ro_ratio) is provided. As it is a

logarithmic coordinate, power of 10 is used to convert the result to non-logarithmic

value.

************************************************************************************/

int MQGetPercentage(float rs_ro_ratio, float *pcurve)

{

return (pow(10,( ((log(rs_ro_ratio)-pcurve[1])/pcurve[2]) + pcurve[0])))

|

เงื่อนไขอื่นๆ

วิธีการชำระเงิน

ชำระเงินผ่านธนาคาร

ชำระเงินด้วยการ Scan QR

ชำระเงินออนไลน์

- ค่าธรรมเนียม 3.9% + 11 THB

- การชำระผ่าน PayPal คุณไม่จำเป็นต้องแจ้งชำระเงิน เนื่องจากระบบจะจัดการให้คุณทันที ที่คุณชำระเงินเสร็จสมบูรณ์

SEARCH(ค้นหา)

CATEGORY

TRACKCODE

TRACK&TRACE

CONTACT US

STATISTICS

| หน้าที่เข้าชม | 5,167,558 ครั้ง |

| ผู้ชมทั้งหมด | 1,566,898 ครั้ง |

| ร้านค้าอัพเดท | 6 ก.ย. 2568 |

MEMBER

- ระดับ{{userdata.dropship_level_name}}

- ไปหน้าหลักตัวแทน

- ทั้งหมด {{(order_nums && order_nums.all)?'('+order_nums.all+')':''}}

- รอการชำระเงิน {{(order_nums && order_nums.wait_payment)?'('+order_nums.wait_payment+')':''}}

- รอตรวจสอบยอดเงิน {{(order_nums && order_nums.wait_payment_verify)?'('+order_nums.wait_payment_verify+')':''}}

- รอจัดส่งสินค้า {{(order_nums && order_nums.wait_send)?'('+order_nums.wait_send+')':''}}

- รอยืนยันได้รับสินค้า {{(order_nums && (order_nums.wait_receive || order_nums.wait_confirm))?'('+(order_nums.wait_receive+order_nums.wait_confirm)+')':''}}

- รอตรวจสอบข้อร้องเรียน {{(order_nums && order_nums.dispute)?'('+order_nums.dispute+')':''}}

- เรียบร้อยแล้ว {{(order_nums && order_nums.completed)?'('+order_nums.completed+')':''}}

- ทั้งหมด {{(order_nums && order_nums.all)?'('+order_nums.all+')':''}}

- รอการชำระเงิน {{(order_nums && order_nums.wait_payment)?'('+order_nums.wait_payment+')':''}}

- รอตรวจสอบยอดเงิน{{(order_nums && order_nums.wait_payment_verify)?'('+order_nums.wait_payment_verify+')':''}}

- รอจัดส่งสินค้า {{(order_nums && order_nums.wait_send)?'('+order_nums.wait_send+')':''}}

- ส่งสินค้าเรียบร้อยแล้ว {{(order_nums && order_nums.sent)?'('+order_nums.sent+')':''}}

Join เป็นสมาชิกร้านค้า