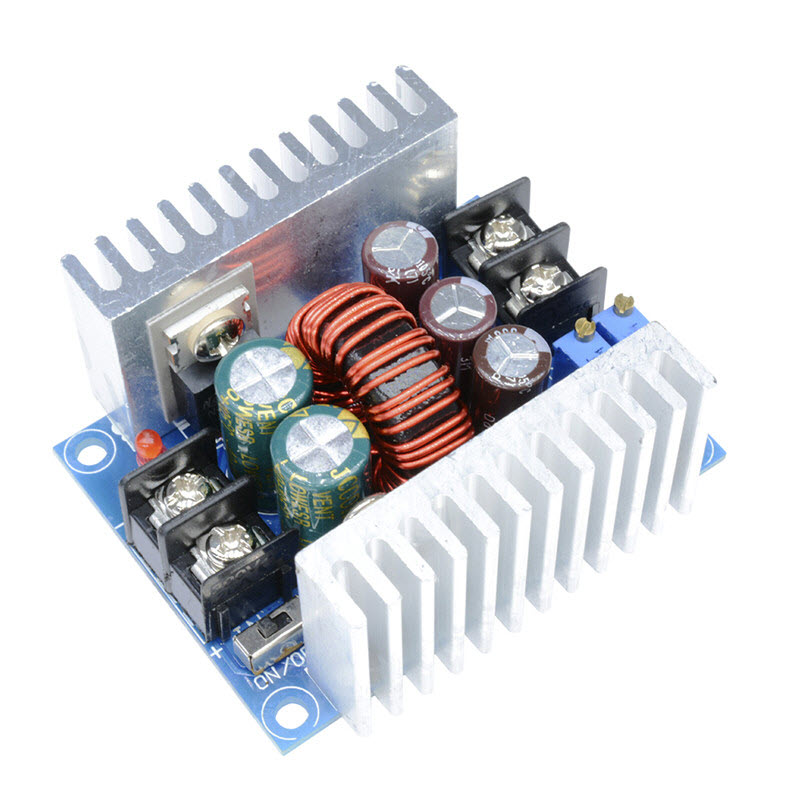

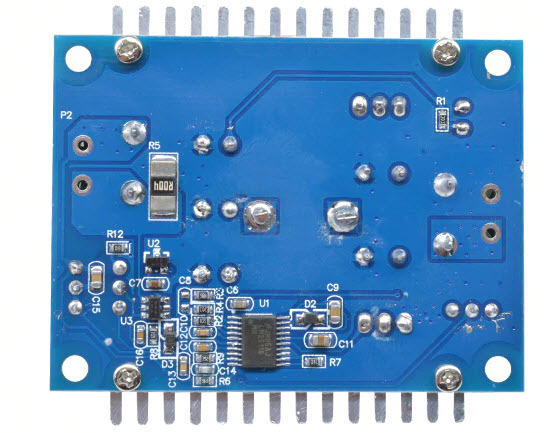

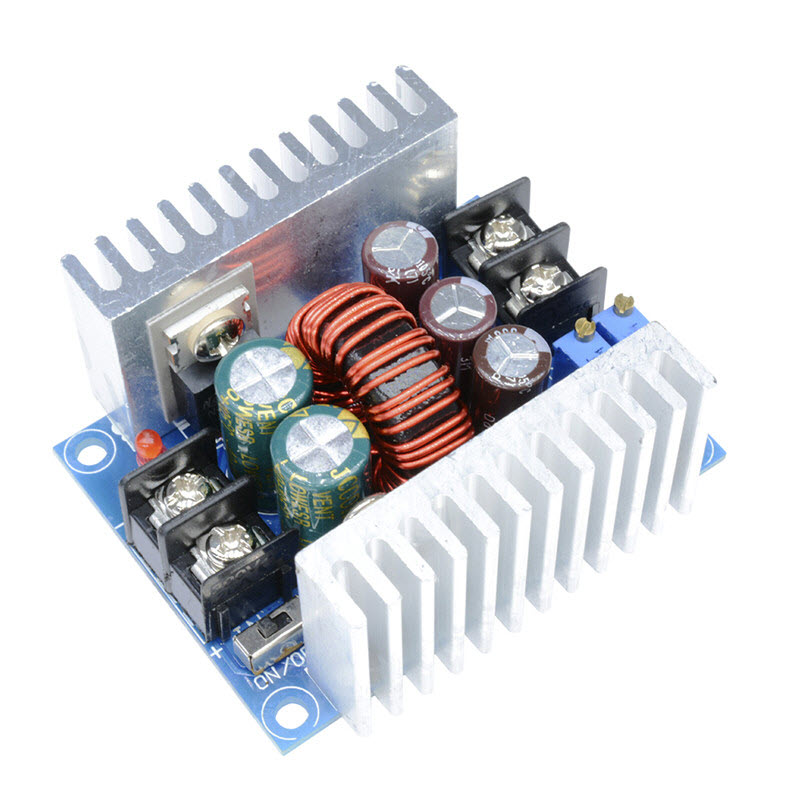

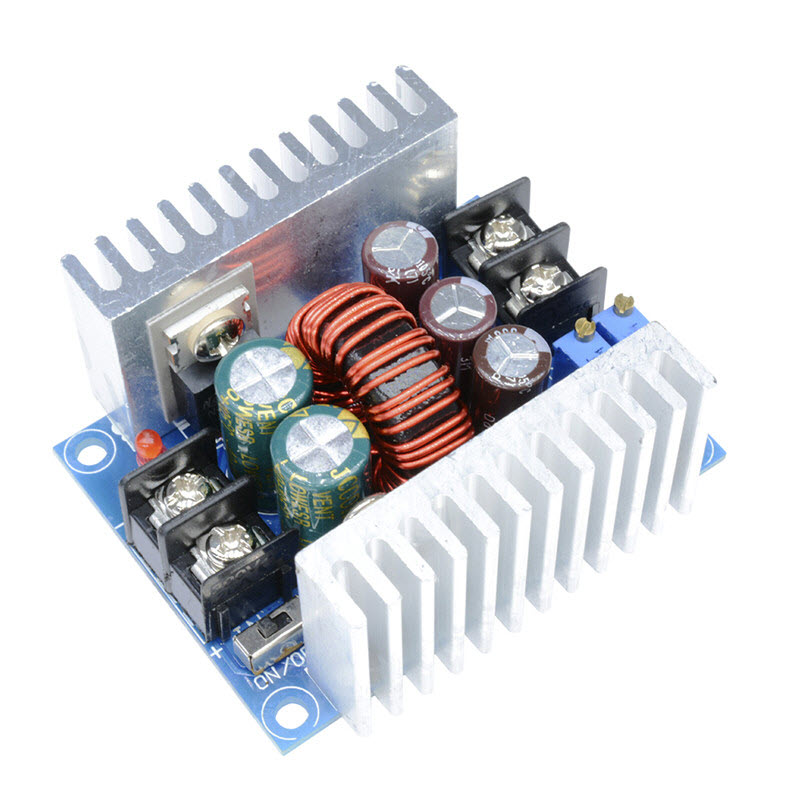

DC-DC 20A 300W buck constant voltage constant current adjustable car power supply LM25116

| รหัสสินค้า | M03232 |

| หมวดหมู่ | DC-DC Step Down |

| ราคา | 154.00 บาท |

| น้ำหนัก | 50 กรัม |

| สถานะสินค้า | พร้อมส่ง |

| ลงสินค้า | 17 พ.ค. 2563 |

| อัพเดทล่าสุด | 7 ก.ค. 2568 |

| จำนวน | ชิ้น |

หยิบลงตะกร้า

Tags : power supply, step-down, แหล่งจ่ายไฟ, dc to dc, LM2596, DC-TO-DC Step up, DC-TO-DC step down, คอนเวอเตอร์, regulator, positive negative, breadboard supply, LM2576, L7805, MP2307, MP1584EN

รายละเอียดสินค้า

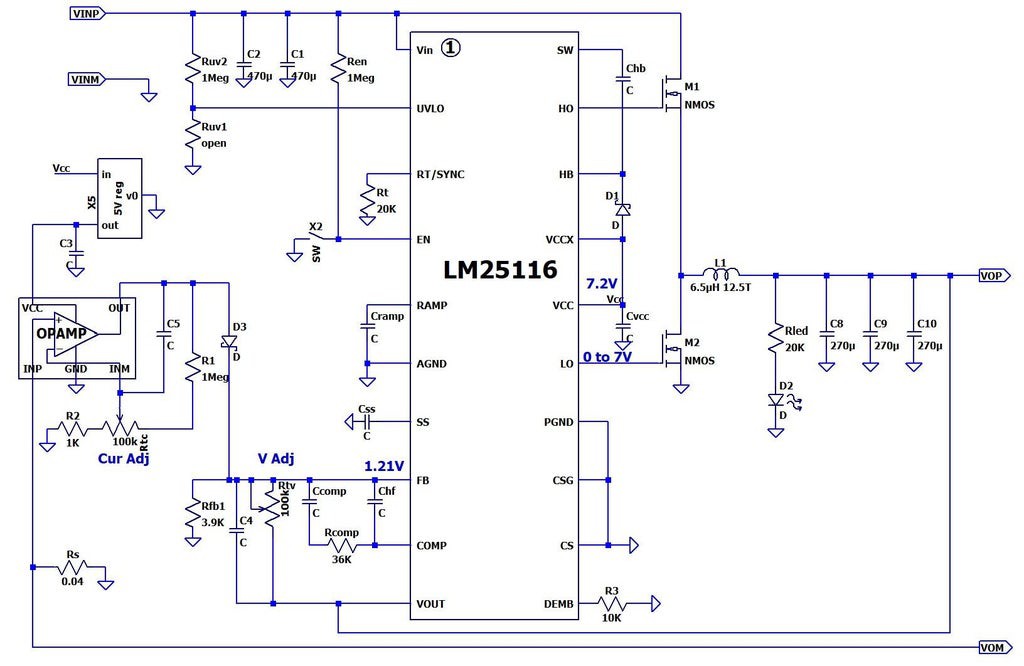

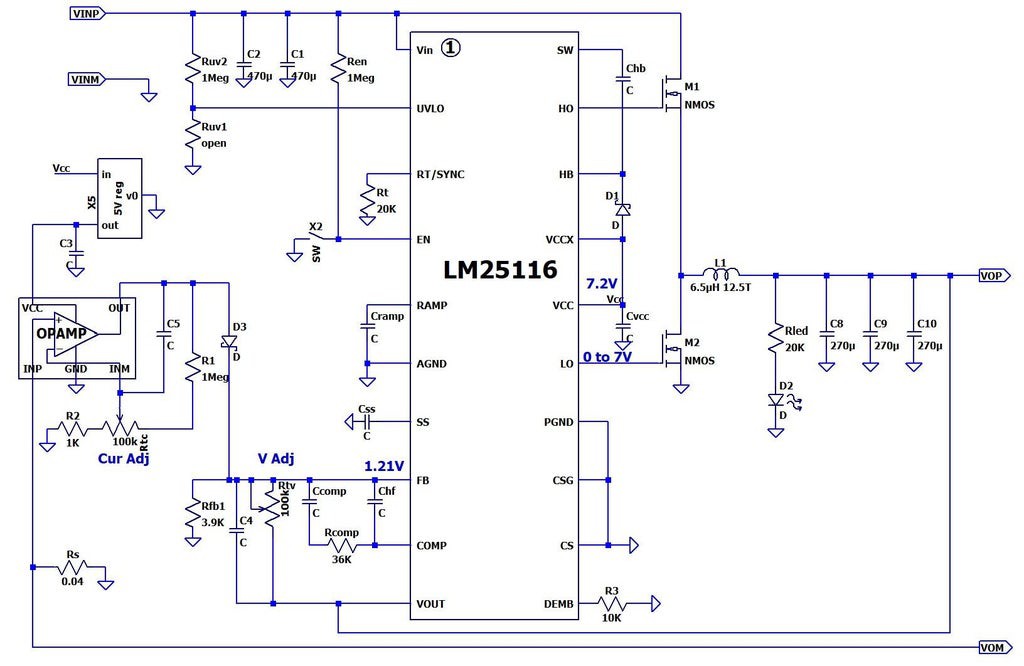

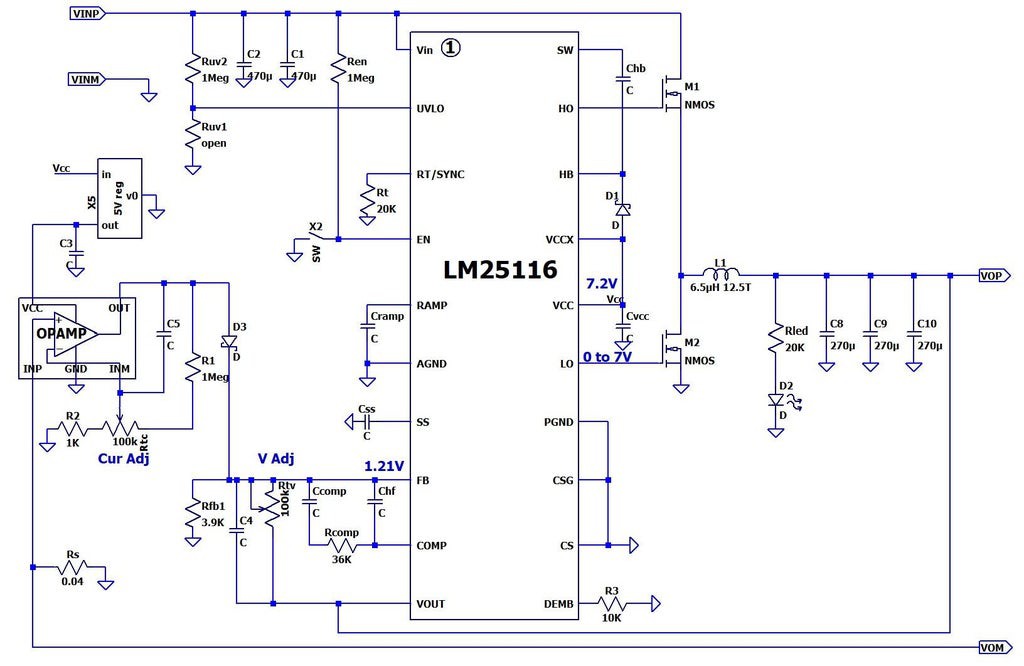

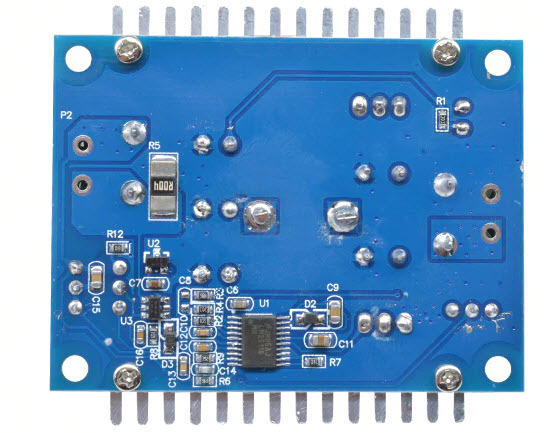

Synchronous rectification technology introduction:

Synchronous rectification is a new technology that uses dedicated power MOSFETs with extremely low on-state resistance to replace rectifier diodes to reduce rectification losses. It can greatly improve the efficiency of the DC / DC converter and there is no dead zone voltage caused by the Schottky barrier voltage. The power MOSFET is a voltage-controlled device, and its volt-ampere characteristic is linear when it is turned on. When the power MOSFET is used as the rectifier, the gate voltage must be synchronized with the phase of the rectified voltage to complete the rectification function, so it is called synchronous rectification. Synchronous rectification technology is to greatly reduce the rectification loss of the output end of the switching power supply, thereby improving the conversion efficiency and reducing the heating of the power supply itself.

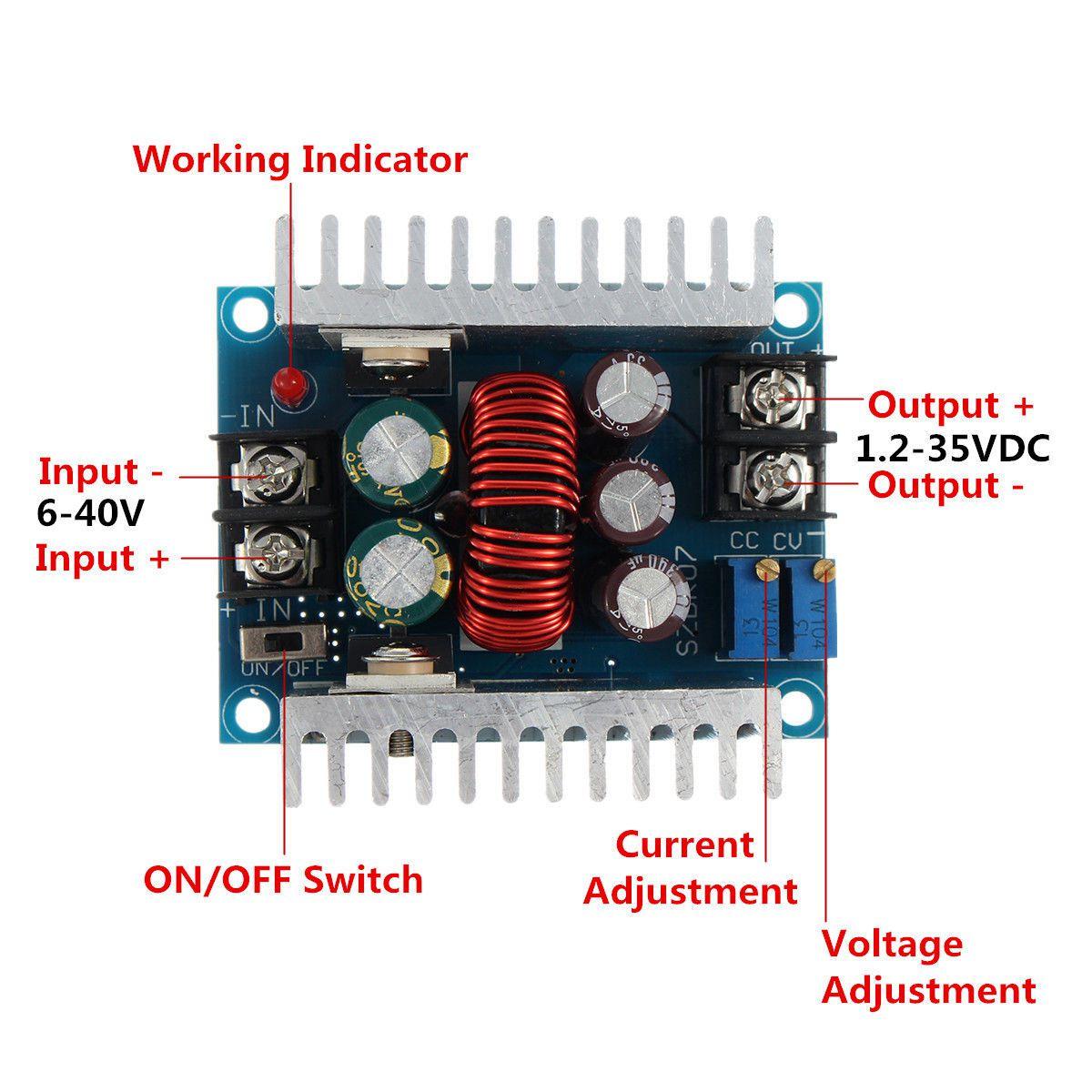

Module parameters:

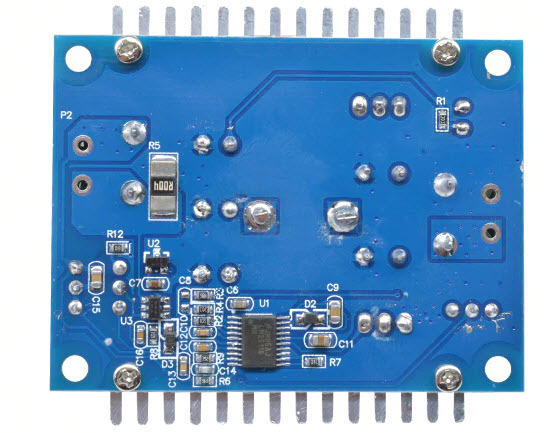

Module nature: synchronous rectification non-isolated buck constant current constant voltage module CC CV charging module

Scope of application: high-power LED constant current drive, lithium battery charging (including ferroelectric), 4V, 6V, 12V, 14V, 24V battery charging, nickel-cadmium nickel-hydrogen battery (battery pack) charging, solar panels, wind turbines

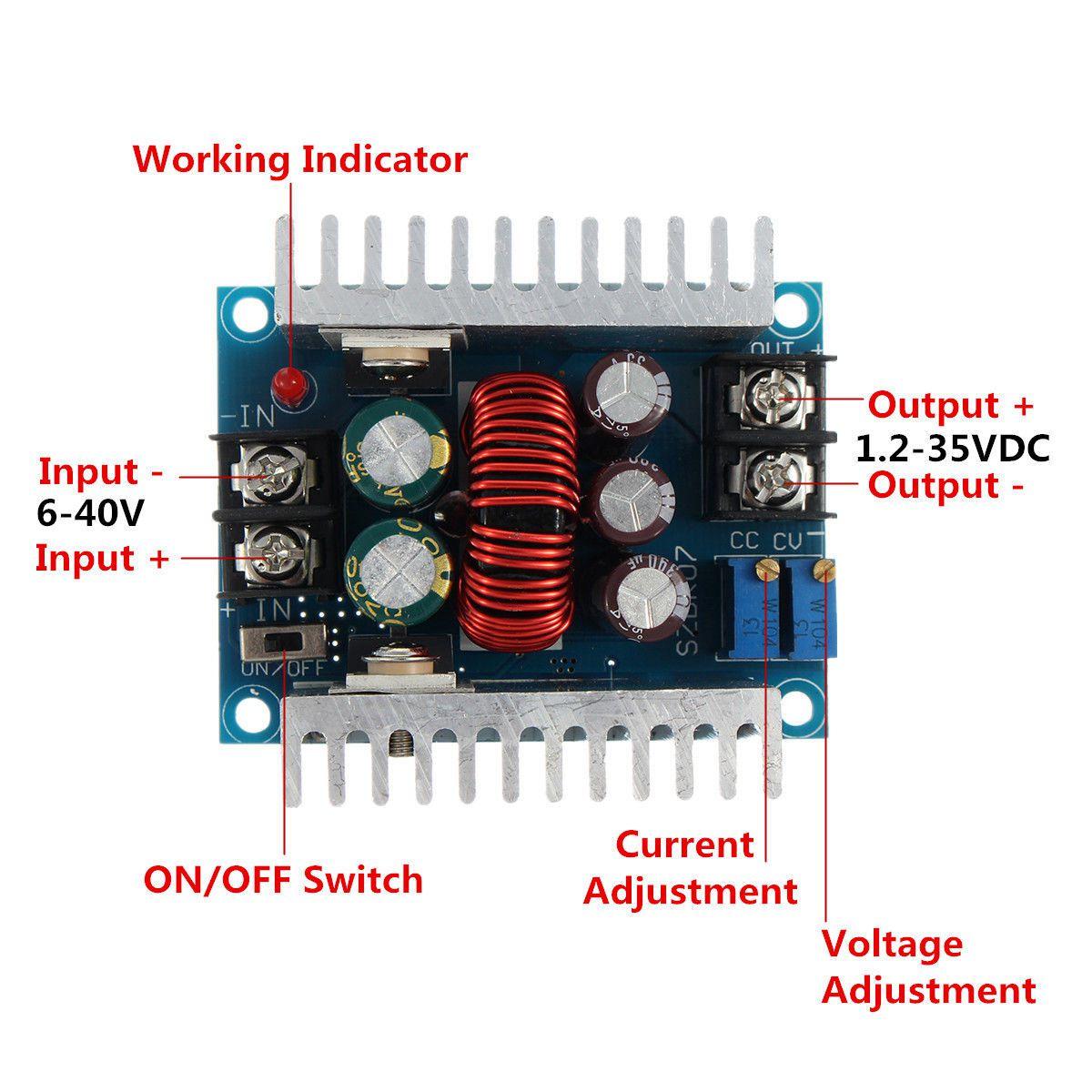

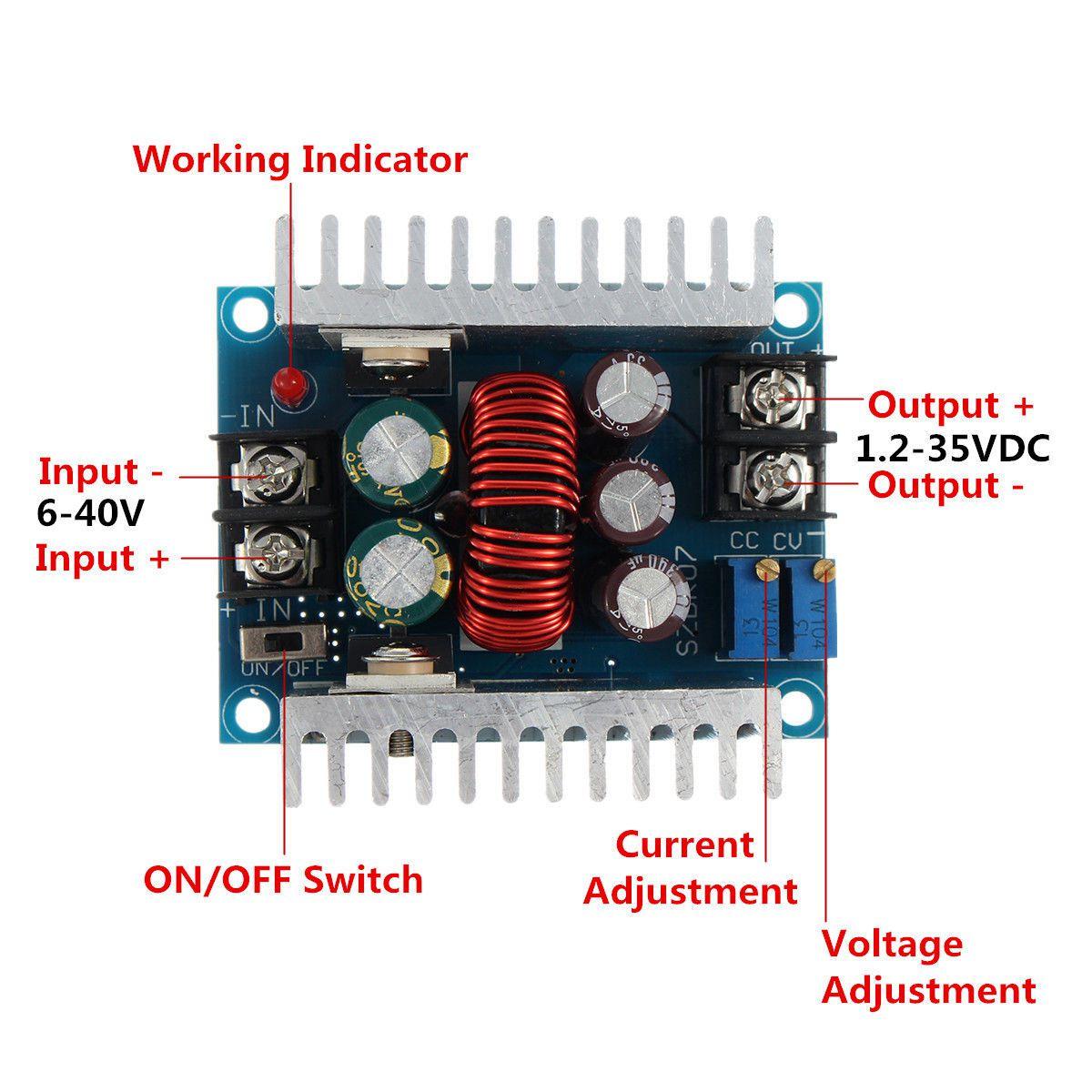

Input voltage: DC6-40V

Output voltage: continuously adjustable (1.2-35VDC) below 32V for a long time (applicable to applications where the input voltage is higher than the output voltage cannot be boosted)

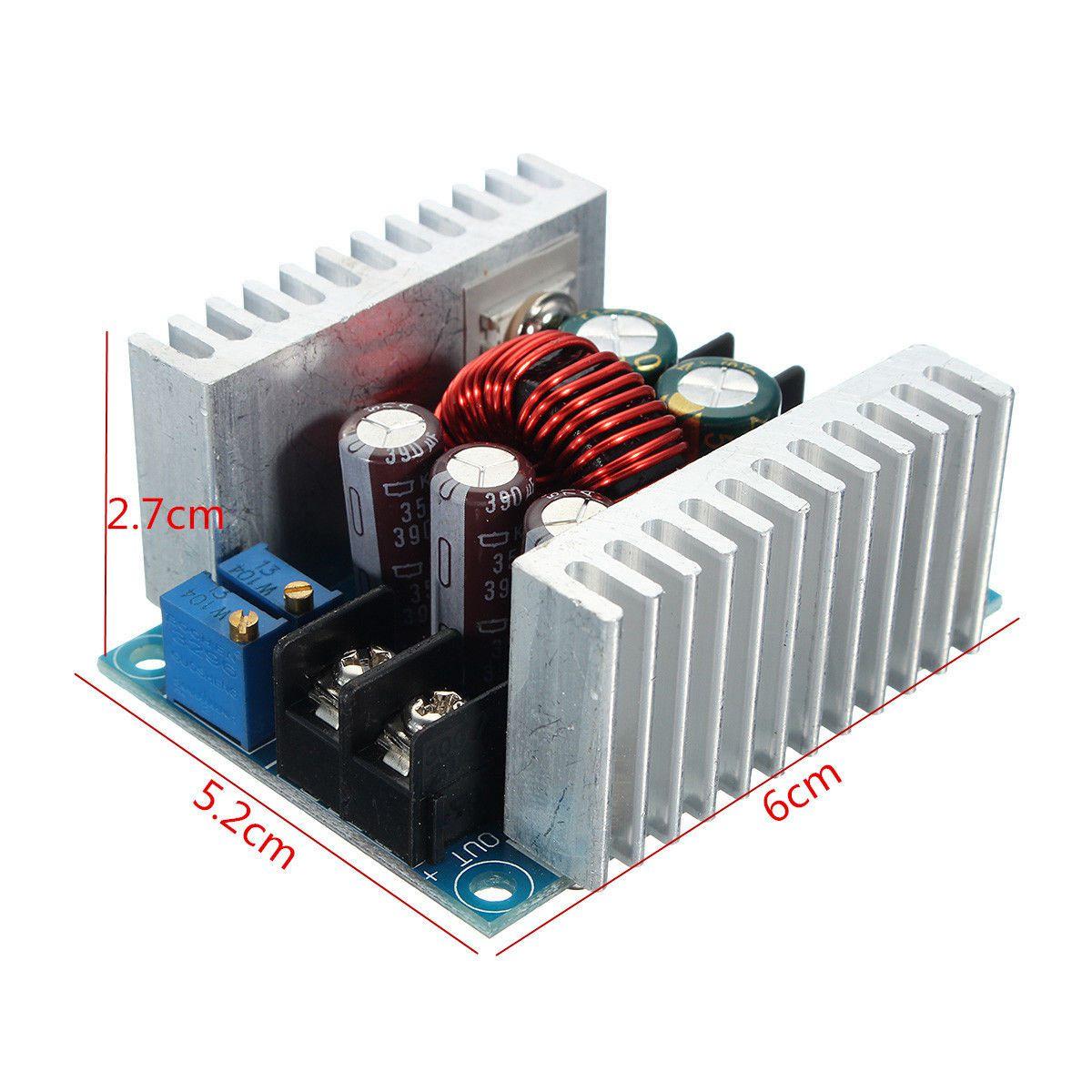

Output current: Maximum 20A within 15A for a long time (please add a fan to dissipate the heat if the temperature of the power tube exceeds 65 degrees, please derate for high voltage output)

Current limit range: 0.2-20A (adjustment) module exceeds 65 degrees, please add a fan.

Minimum pressure difference: 3V

Working frequency: 150KHZ

Conversion efficiency: up to about 96% efficiency is related to pressure difference and use environment

Output ripple: Ripple is about 50mV (no noise included) 20M bandwidth (for reference only) input 24V measured

Working temperature: -10 ℃ to + 75 ℃) (Please pay attention to the temperature of the power tube in actual use, if the temperature is too high, please strengthen the heat dissipation or derating)

Potentiometer adjustment direction: clockwise (increasing), counterclockwise (decreasing)

Output short-circuit protection: Yes (instantaneous protection) constant current (currently set constant current value cannot be short-circuited for a long time )

Input reverse connection protection: none,

Output anti-backflow: No, for load self-charged or inductive load requires 2 extra tubes!

Wiring method: terminal

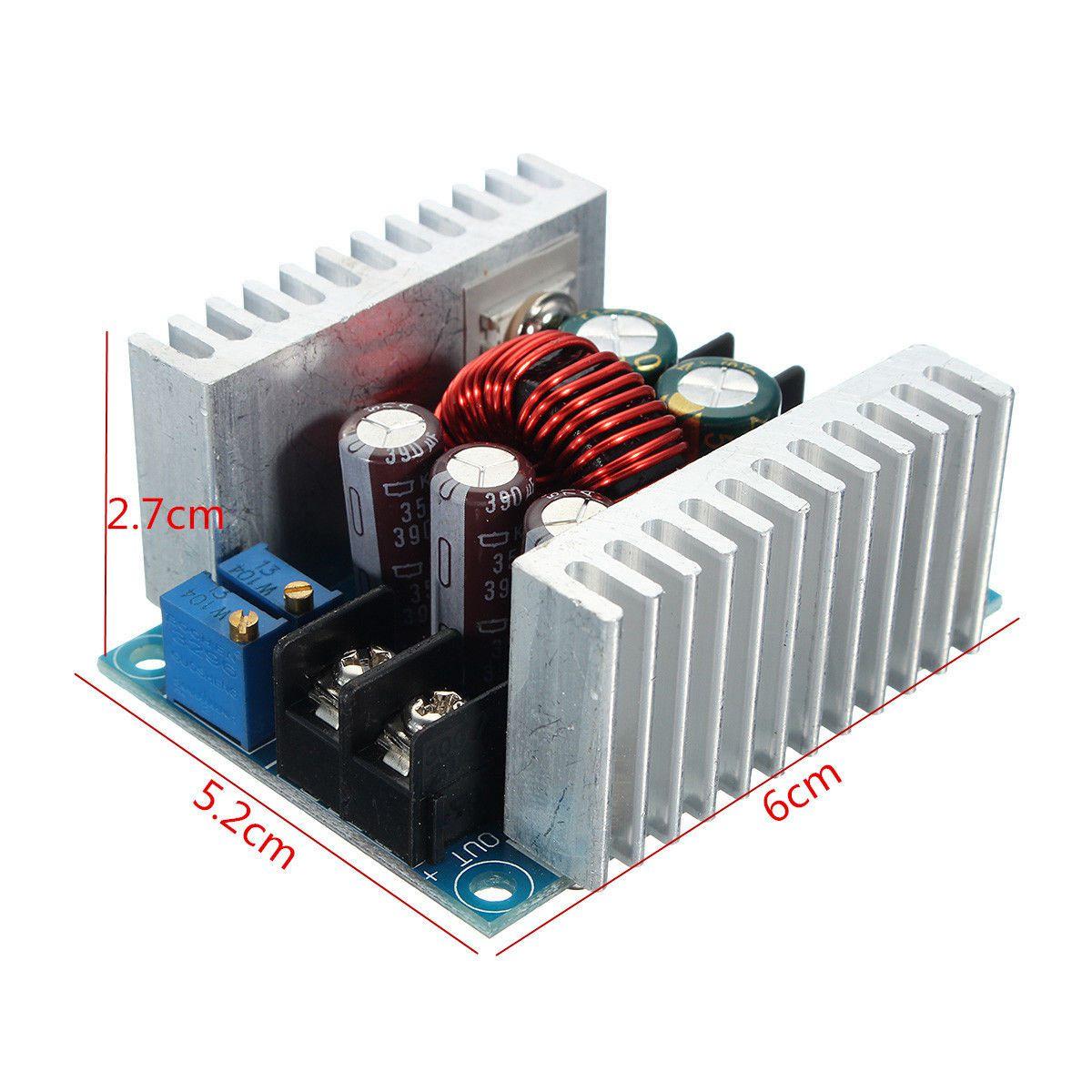

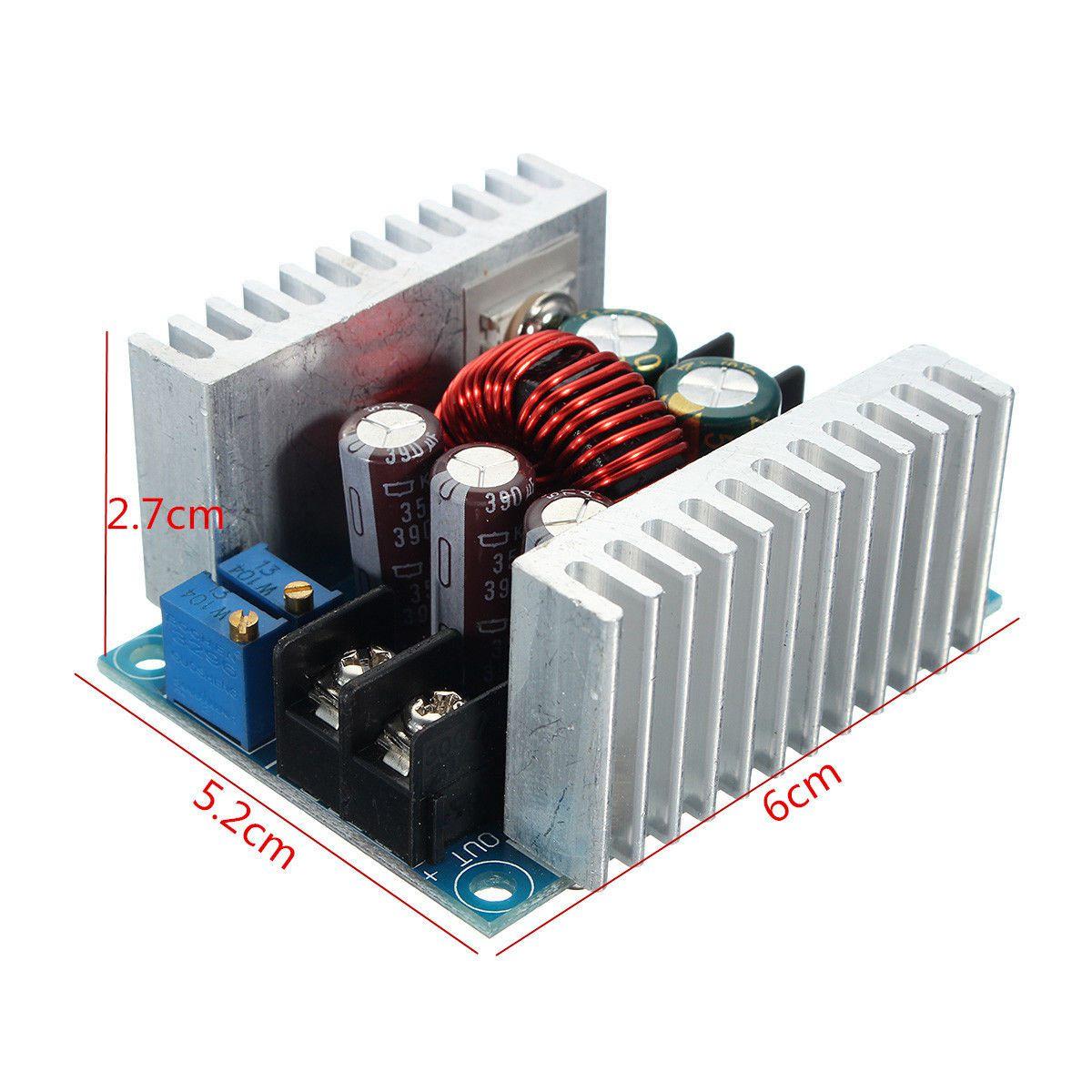

Module size: 60 * 53 * 30MM

Net weight: about 85 grams

Output current adjustment method:

1. Adjust the CV potentiometer and set the output voltage to the voltage value you need according to your load requirements.

2. Set the CC potentiometer about 30 turns counterclockwise (that is, set the output current to the minimum), connect the LED, and adjust the CC potentiometer to the current you need. For battery charging, after the battery is discharged, connect it to the output and adjust the CC to the current you need. (When charging, be sure to use the discharged battery to adjust it, because the battery has more power. More, the smaller the charging current.)

Wiring instructions:

OUT +: positive output

OUT-: negative output

+ IN: positive input-IN:

negative input

CV: output voltage adjustment

CC: output current adjustment

EN: enable, low level to turn off the output; pause, high voltage level effective

When the input and output are grounded, no-load CV output constant voltage, CC output constant current

cross-current constant voltage mode: The output voltage should be lower than 12 V

Input 12V output should be adjusted below 10V. Under constant current work. It can't be constant pressure, and it can't be constant current under constant pressure work. pick one of two

https://hackaday.io/project/185105-low-cost-solar-panel-solution-mppt-sun-tracker/log/205600-mppt-controller-hardware

https://hackaday.io/project/185105-low-cost-solar-panel-solution-mppt-sun-tracker/log/205600-mppt-controller-hardware

วิธีการชำระเงิน

ชำระเงินผ่านธนาคาร

ชำระเงินด้วยการ Scan QR

กิตติ แซ่เอี้ยว

096-xxxxxx-3

Accept All Banks | รับเงินได้จากทุกธนาคาร

ชำระเงินออนไลน์

- ค่าธรรมเนียม 3.9% + 11 THB

- การชำระผ่าน PayPal คุณไม่จำเป็นต้องแจ้งชำระเงิน เนื่องจากระบบจะจัดการให้คุณทันที ที่คุณชำระเงินเสร็จสมบูรณ์

Recently viewed

SEARCH(ค้นหา)

CATEGORY

TRACKCODE

*ใส่ เบอร์มือถือ หรือ email ที่ใช้ในการสั่งซื้อ

TRACK&TRACE

CONTACT US

096-898-2243

mcucity123@gmail.com

STATISTICS

| หน้าที่เข้าชม | 5,183,795 ครั้ง |

| ผู้ชมทั้งหมด | 1,583,135 ครั้ง |

| ร้านค้าอัพเดท | 1 พ.ย. 2568 |

MEMBER

คุณเป็นตัวแทนจำหน่าย

- ระดับ{{userdata.dropship_level_name}}

- ไปหน้าหลักตัวแทน

ระดับสมาชิกของคุณ ที่ร้านค้านี้

รายการสั่งซื้อของฉัน

- ทั้งหมด {{(order_nums && order_nums.all)?'('+order_nums.all+')':''}}

- รอการชำระเงิน {{(order_nums && order_nums.wait_payment)?'('+order_nums.wait_payment+')':''}}

- รอตรวจสอบยอดเงิน {{(order_nums && order_nums.wait_payment_verify)?'('+order_nums.wait_payment_verify+')':''}}

- รอจัดส่งสินค้า {{(order_nums && order_nums.wait_send)?'('+order_nums.wait_send+')':''}}

- รอยืนยันได้รับสินค้า {{(order_nums && (order_nums.wait_receive || order_nums.wait_confirm))?'('+(order_nums.wait_receive+order_nums.wait_confirm)+')':''}}

- รอตรวจสอบข้อร้องเรียน {{(order_nums && order_nums.dispute)?'('+order_nums.dispute+')':''}}

- เรียบร้อยแล้ว {{(order_nums && order_nums.completed)?'('+order_nums.completed+')':''}}

- ทั้งหมด {{(order_nums && order_nums.all)?'('+order_nums.all+')':''}}

- รอการชำระเงิน {{(order_nums && order_nums.wait_payment)?'('+order_nums.wait_payment+')':''}}

- รอตรวจสอบยอดเงิน{{(order_nums && order_nums.wait_payment_verify)?'('+order_nums.wait_payment_verify+')':''}}

- รอจัดส่งสินค้า {{(order_nums && order_nums.wait_send)?'('+order_nums.wait_send+')':''}}

- ส่งสินค้าเรียบร้อยแล้ว {{(order_nums && order_nums.sent)?'('+order_nums.sent+')':''}}

Join เป็นสมาชิกร้านค้า

ร้านmcucity

/www.mcucity.com/

Join เป็นสมาชิกร้าน

818

สมัครสมาชิกร้านนี้ เพื่อรับสิทธิพิเศษ

หน้าแรก | วิธีการสั่งซื้อสินค้า | แจ้งชำระเงิน | บทความ | เว็บบอร์ด | เกี่ยวกับเรา | ติดต่อเรา | ตะกร้าสินค้า | Site Map

ร้านค้าออนไลน์

Inspired by

LnwShop.com (v2)

คุณมีสินค้า 0 ชิ้นในตะกร้า สั่งซื้อทันที

สินค้าในตะกร้า ({{total_num}} รายการ)

ขออภัย ขณะนี้ยังไม่มีสินค้าในตะกร้า

ราคาสินค้าทั้งหมด

฿ {{price_format(total_price)}}

- ฿ {{price_format(discount.price)}}

ราคาสินค้าทั้งหมด

{{total_quantity}} ชิ้น

฿ {{price_format(after_product_price)}}

ราคาไม่รวมค่าจัดส่ง

➜ เลือกซื้อสินค้าเพิ่ม